Beer Dispensing Challenge

The customer had been using an industry standard Italian beer valve for many years and now sought a solution which would not be affected by pressure change and so deliver a consistent volume. It needed to be smaller and lighter and not heat up the beer when the coil was overvoltage to overcome up to 60 psi static pressure, one of the problems with the original valve.

In large facilities where the beer kegs could be a long distance from the point of sale, in the basement of a stadium for example, the beer needs to be pumped at a higher pressure to make sure it reaches its destination. At this higher pressure (60 psi), it is necessary to put 28 Volts through the 24 Volt coil, or it will not open. The overvoltage causes the beer to heat up and after constant use, at ‘half time’, this can be as much as 3-4 deg C which causes customer dissatisfaction, as the beer is best enjoyed cool. With the automatic version of the beer dispenser, it is important to get consistent volume delivered to the customer as too little beer requires a top up and time wasted by the server, and over filling costs to the vendor. This was the case with the original valve hence the interest in improvement.

MAC develops valves for various filling applications to attain greater consistency and repeatability, in terms of the minimum acceptable volume and only a small overfill within its filling tolerance. The fact that MAC Valves are unaffected by pressure variation due to their balanced design and can be modified for accurate repeatability, means that they are the preferred choice for beverage manufacturers particularly when the drink is of high value.

The challenge was set for MAC to use its inherent valve design strengths to create a new Advanced Beer Valve for the customer to give them the competitive advantage in their market place.

Engagement

Site visits – problem identification

Initially we presented the new Liquid Bullet Valve Technology from MAC which was of interest due its compact size and incredibly high cycle life. The potential specification was developed taking into account the issues the customer wished to overcome.

Concept / Design

After several visits 4 key design features were identified.

- A media separated coil

- Smaller, lighter and more compact design

- Lower power consumption – less heat produced at highest pressure (60psi)

- Eventual EN1935 Certification

Prototyping

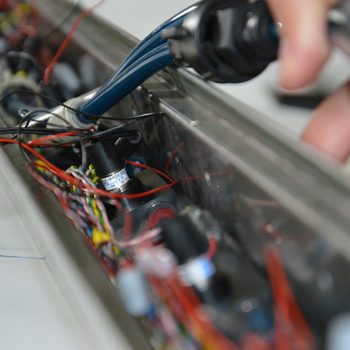

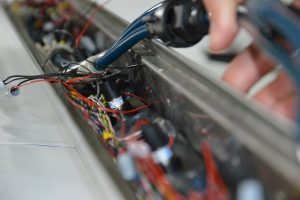

After several months, numerous visits, conference calls and various prototypes being made, MAC came up with a complete new design which was delivered for testing.

The latest version of the MAC Beer Valve combined MAC features that our customers prefer and a laminar flow path.

The results:-

- Head was 3 cm – preferred 0.5cm

- 12 second pint – preferred 7 seconds – higher flow rate required

- Higher pressure range required from 12-60 psi

- Design simplification required to ease cleaning

- Slightly smaller output tube required 12mm to 10mm

- Repositioning of armature which should be closer to the output tube to reduce turbulence which caused the slightly greater head than required.

The information from the tests were communicated to MAC Product Design and although the customer was impressed by the progress, further development was required to give the customer the optimal solution.

The New Version was to have improved flow to achieve the 7 second pint delivery, a reduction in interior turbulence to reduce the beer head, a simpler design to ease cleaning and no leakage at the highest pressure (60psi).

Each iteration developed the solution further and both parties learnt from the experience. The latest version of prototypes are being produced and are expected to be delivered towards the end of the year with full production pencilled in for the New year.

The latest version of the MAC beer valve

Solution

Work in progress with refinement of prototypes until the customer is completely satisfied and can incorporate the valves into his multi pour dispensers. which are used at stadiums and festivals to give the customer the quickest service possible.

Benefits

The benefits expected for the client are a reliable, repeatable valve designed to accurately dispense any beer in the shortest time with minimal cleaning required and no heating of the beer at the highest pressures.

This new MAC Advanced Beer Valve design features translate into greater customer satisfaction with cooler beer and more accurate automatic dispensing saving the vendors money and time plus the upgrade gives our client a competitive advantage in the market place which is likely to result in increases sales and new customers.